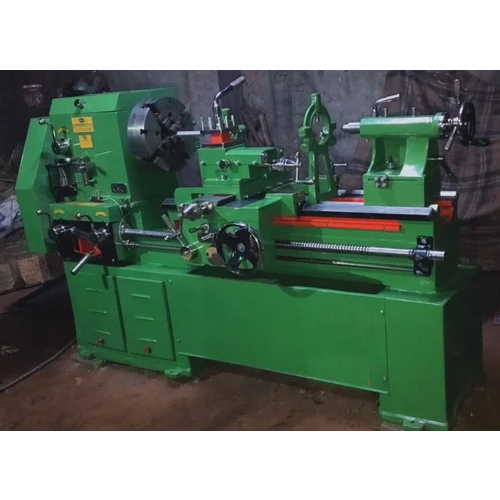

Light Duty Lathe

Light Duty Lathe Specification

- Features

- Sturdy Frame, Precision Gear Box, Hardened Bed

- Model No

- LDL-1700

- Motor Power

- 2 HP

- Cooling System

- Water Based

- Drive

- Belt Drive

- Frequency

- 50 Hz

- Noise Level

- Less than 70 dB

- Accuracy

- 0.02 mm

- Operating Temperature

- 10C - 40C

- Power Rating

- 2 HP

- Frame Type

- Heavy Steel

- Control System

- Manual

- Production Capacity

- 5-10 units/month

- Machine Type

- LATHE

- Lubricating System

- Automatic

- Voltage

- 220V/380V

- Product Type

- Other

- Technology

- Conventional

- Power Source

- Electricity

- Operating Type

- Manual

- Power

- 2 HP

- Surface Treatment

- Painted

- Dimension (L*W*H)

- 1700 x 700 x 1200 mm

- Weight (kg)

- 400 Kilograms (kg)

- Color

- Green

- Warranty

- 1

- Usage & Applications

- Turning, Facing, Threading, Drilling

- Lead Screw Pitch

- 4 TPI

- Tailstock Quill Travel

- 100 mm

- Tool Post Type

- Four-way

- Max Turning Diameter

- 300 mm

- Carriage Travel

- 700 mm

- Vibration Level

- Low

- Main Spindle Nose

- MT4

- Safety

- Emergency Stop Button

- Chuck Size

- 150 mm

- Bed Type

- Cast Iron, Hardened & Ground

- Power Consumption

- Approx. 1.5-2 kW

- Spindle Bore

- 38 mm

- Swing Over Bed

- 320 mm

- Distance Between Centers

- 800 mm

About Light Duty Lathe

Light Duty Lathe

We deals with latest technologies based light duty lathe machines that have been designed to make industrial tasks easier, faster and error free. Bed is made from 25 Grade Cast Iron of 180 BHN hardened, strictly inspected with Micro level, Hardness Tester and Straight Edge

Precision Engineering and Robust Build

Engineered from a sturdy cast iron frame with a hardened and ground bed, this lathe ensures exceptional rigidity and minimal vibration. The precision gear box and four-way tool post support intricate machining and consistent accuracy of up to 0.02 mm. Its compact dimensions and noise level below 70 dB make it suitable for small workshops and educational settings alike.

Versatile Application and Control

Designed for manual operation, the LDL-1700 model can handle turning, facing, threading, and drilling tasks with its 2 HP power rating. The spindle bore of 38 mm and 150 mm chuck size permit flexible material handling. The water-based cooling and automatic lubricating systems optimize both safety and performance throughout extended machining operations.

Safety and Maintenance Features

Prioritizing operator safety, the machine comes equipped with an emergency stop button and operates between 10C - 40C for reliable performance. The automatic lubrication system reduces maintenance frequency, ensuring lasting durability. Surface treatment with high-quality paint enhances the machines resistance to corrosion, making it a reliable investment for manufacturers.

FAQs of Light Duty Lathe:

Q: How do I operate the Light Duty Lathe for turning and threading tasks?

A: This lathe is operated manually using its control system. For turning and threading, securely mount the workpiece between centers or in the chuck, select the desired tool on the four-way post, and adjust speed and feed using the gear box. Always ensure the machine is properly lubricated and the cooling system is active during operation.Q: What are the safety features provided with this lathe machine?

A: The Light Duty Lathe comes equipped with an emergency stop button for immediate shutdown during emergencies, a sturdy frame for stable operation, and low noise/vibration levels for improved operator comfort. Ensure to follow standard safety protocols and keep the workspace clear for safe usage.Q: When should I perform maintenance on the Light Duty Lathe?

A: Routine maintenance should be carried out according to the manufacturers recommendations generally after every use for cleaning and lubrication, with thorough inspections monthly. The automatic lubricating system assists in keeping components in good condition, but periodic checks for oil levels and system integrity are advisable.Q: Where can this lathe be effectively used?

A: This machine is ideal for small manufacturing workshops, maintenance departments, technical education institutes, and light-duty production settings. Thanks to its moderate size and noise levels, it fits well into compact industrial spaces while delivering reliable, precise machining.Q: What benefits does the cast iron, hardened & ground bed provide?

A: The cast iron, hardened & ground bed ensures longevity, minimal wear, and high dimensional accuracy. It absorbs vibrations effectively, producing better finished surfaces and maintaining precision even during extended machining tasks.Q: How does the automatic lubricating system work, and what is its advantage?

A: The automatic lubricating system continuously supplies oil to critical moving parts, reducing friction and wear. This minimizes manual intervention, enhances component lifespan, and ensures consistent, reliable operation throughout the lathes service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lathe Machines Category

Heavy Duty Lathe Machine

Price 140000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Hydraulic

Operating Type : Manual

Surface Treatment : Painted

Warranty : yes

All Geared Head Lathe Machine

Price 200000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Hydraulic

Operating Type : Automatic

Surface Treatment : Painted

Warranty : yes

Light Duty Lathe Machine

Price 90000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Hydraulic

Operating Type : Manual

Surface Treatment : Painted

Warranty : yes

All Geared light duty Lathe For ITI

Price 165000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Hydraulic

Operating Type : Automatic

Surface Treatment : Painted

Warranty : yes